Touchscreen technology has evolved dramatically over the past few decades, transforming the way we interact with devices across industries. From smartphones and tablets to industrial workstations and interactive kiosks, touch screens have become an everyday interface that simplifies communication and boosts efficiency. The journey from early, pressure-based panels to today’s advanced and highly responsive displays reveals just how innovative this technology has become.

When we look closer at the types of touch screen technology, it becomes clear that each was designed with specific uses and environments in mind. Among the four most recognized varieties—resistive, surface acoustic wave, infrared, and projected capacitive—each offers its own strengths and limitations. Understanding how these technologies differ helps in selecting the right touch interface for any application. Below is a detailed look at how these different touch screens work and why iPlanTables workstations rely on the most advanced of them all: projected capacitive technology.

Types of Touch Screen Technology – Introduction to Resistive Touch Screen Technology

Resistive touch screens are often considered the pioneers of modern touchscreen interaction. They were among the earliest designs to enter commercial use and remain an important foundation for how we understand touch input today.

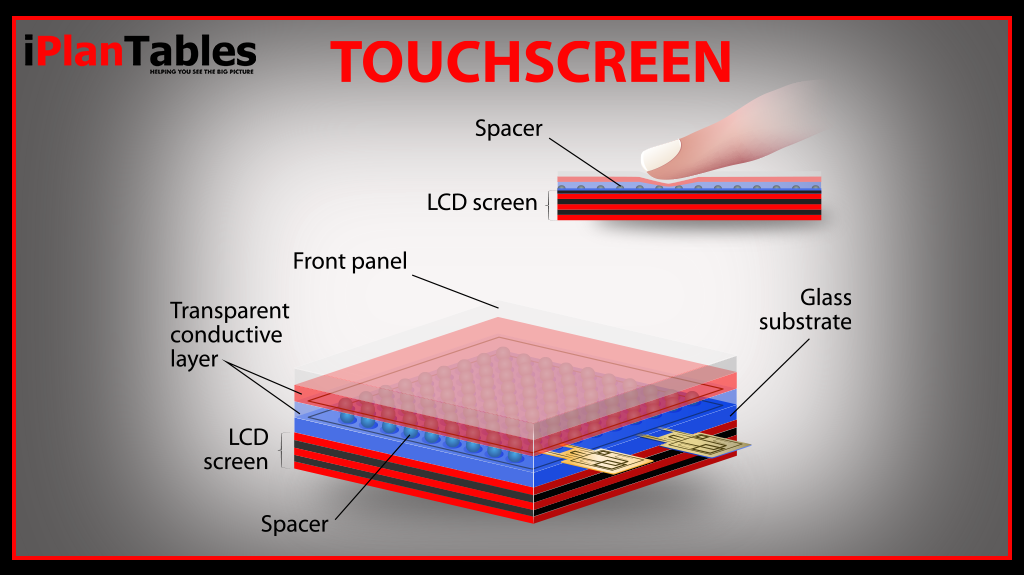

A resistive panel is constructed with two thin layers—a glass panel and a plastic film—separated by a small air gap or an inert gas. Both layers are coated with a conductive material. When a finger or stylus presses down on the surface, the two layers come into contact, creating a voltage that flows between them. The system measures this change in voltage to determine the precise X and Y coordinates of the touch.

Because resistive panels respond to pressure rather than electrical conductivity, they can be activated by virtually anything—your fingertip, a stylus, or even a gloved hand. This makes them versatile for certain industrial and retail settings where gloves or other tools are commonly used. For example, many grocery store signature pads still rely on this technology, requiring only a simple stylus to capture a digital signature.

However, resistive touch panels are not without drawbacks. They are generally less sensitive than other touchscreen types, which can make gestures such as swiping or multi-touch interactions difficult. The plastic top layer is also more prone to scratches and wear, and the technology is limited to single-point contact. While cost-effective and durable enough for basic tasks, resistive screens often fall short in environments where precision and speed are critical.

What is Surface Acoustic Wave Touch Screen Technology?

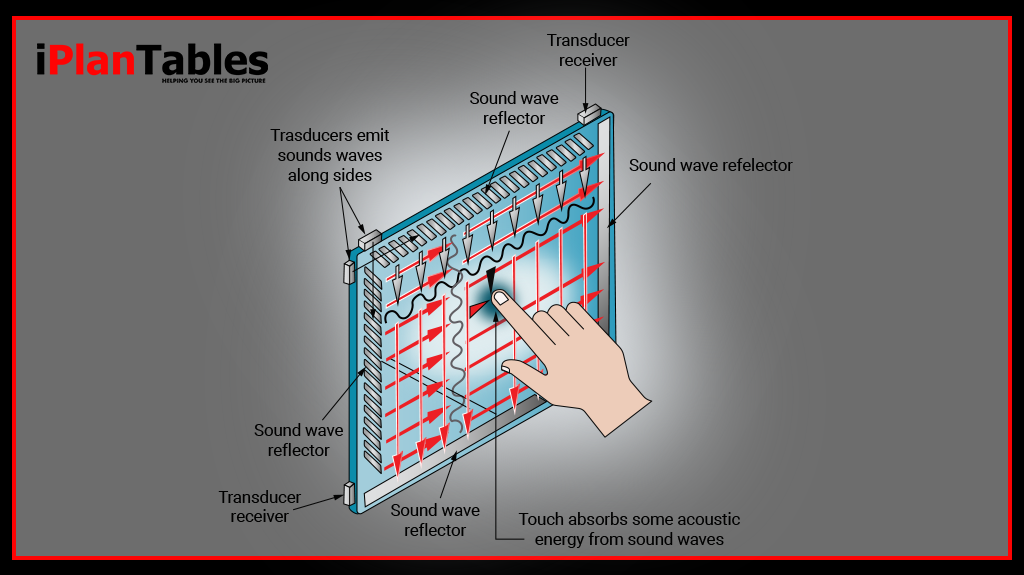

Surface acoustic wave (SAW) technology represents an important step forward in the evolution of touch panels. Instead of relying on pressure, SAW screens use ultrasonic sound waves across a glass surface. These waves are generated by piezoelectric transducers placed along the edges of the screen.

When a finger or other object touches the surface, the ultrasonic waves are disrupted. Sensors detect the precise point of interference, allowing the system to determine the exact coordinates of the touch. This method provides excellent image clarity because it does not require any additional layers or coatings that might cloud the display.

Surface acoustic wave screens are known for their high sensitivity and accuracy. They can be used with bare fingers, gloved hands, or soft styluses, making them suitable for a variety of professional applications. Another advantage is their resistance to water and other liquids, which allows them to perform reliably even in challenging conditions.

Despite these benefits, SAW touch panels are generally more expensive than resistive panels. Their reliance on exposed glass surfaces also makes them somewhat more delicate and less common than other touchscreen types. Still, they remain a dependable option in settings where precision and durability are equally important.

Understanding Infrared Touch Screen Technology

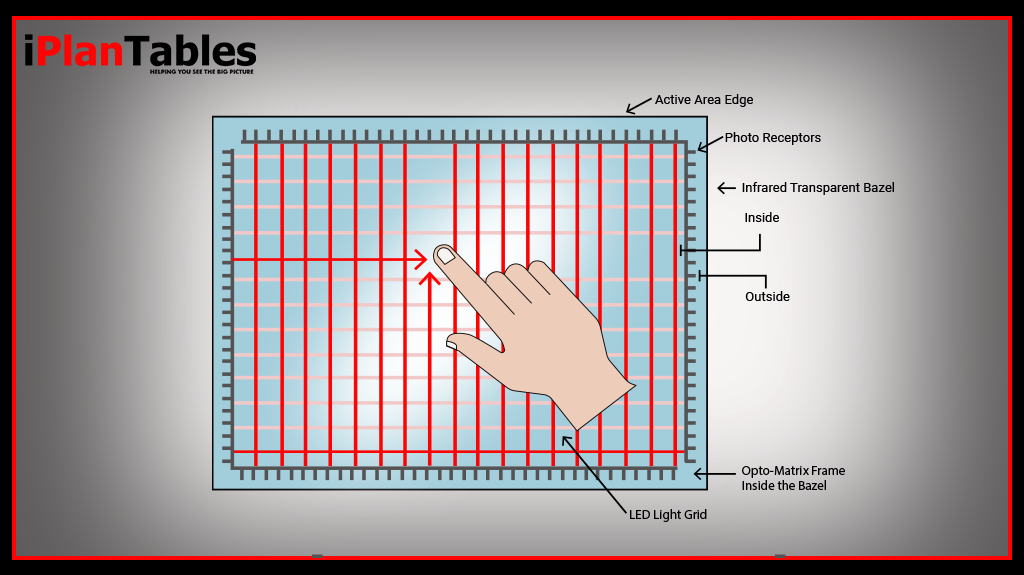

Infrared (IR) touch screens represent one of the most sophisticated approaches to touch detection. Instead of relying on mechanical pressure or acoustic waves, IR technology uses an invisible grid of infrared light beams. These beams are created by pairs of LEDs and photodetectors arranged around the edges of the display.

When a finger or any other object interrupts the beams, the disruption is measured to pinpoint the exact X and Y coordinates of the touch. This process requires no physical contact with the screen surface itself, which means the display can remain completely protected by a sheet of durable glass without affecting sensitivity.

One of the greatest advantages of infrared touch screens is their ability to recognize multiple points of contact at once, enabling true multi-touch gestures. They are highly sensitive and function reliably with bare fingers, gloves, or styluses. Their durability makes them ideal for heavy-duty use and even outdoor environments.

However, IR panels can be sensitive to external light interference, such as direct sunlight, which may affect performance. They also tend to be among the more expensive options, and their responsiveness, while excellent, may not match the instantaneous feel of more modern capacitive systems.

iPlanTables Favorite — Projected Capacitive (PCAP) Technology

At the forefront of modern touch interfaces is projected capacitive (often referred to as PCAP) technology—the same principle used in smartphones and high-end interactive displays. iPlanTables has chosen projected capacitive technology for every workstation model, whether it’s a 43-inch display or a massive 75-inch screen, because of its unmatched precision and reliability.

Projected capacitive touch screens consist of a fine matrix of conductive elements embedded within the glass. When an electrical current passes through, it generates an electrostatic field just above the surface. When a conductive object, such as a finger or a special stylus approaches the screen, it disturbs the electrostatic field. This disruption allows the system to instantly calculate the exact location of the touch.

The result is an exceptionally accurate and responsive user experience. PCAP screens support multi-touch functionality, enabling smooth pinch-to-zoom gestures, quick scrolling, and effortless on-screen navigation. They are designed to withstand heavy use without losing sensitivity, making them ideal for demanding professional environments like construction project management.

Another benefit is their ability to deliver crystal-clear images. Because there are no additional layers between the user and the display, visuals remain sharp and bright. PCAP technology is also highly durable, resisting scratches, dust, and everyday wear. This combination of speed, accuracy, and resilience makes it the preferred choice for iPlanTables workstations, where professionals depend on large touch screens to review complex construction drawings and collaborate in real-time.

Why Choosing the Right Technology Matters

The variety of touch screen technologies highlights how critical it is to match the right solution to the right task. Resistive panels may still serve well in retail environments or industrial settings where cost-effectiveness and simple inputs matter. Surface acoustic wave screens excel in environments that require precision and liquid resistance, while infrared screens are favored for multi-touch, large-format installations.

Yet for advanced project management needs—where professionals demand instant response, clarity, and seamless multi-touch capabilities—projected capacitive technology stands out as the clear leader. It provides the responsiveness and accuracy that modern workflows demand, ensuring that every touch is registered without delay or error.

Final Thoughts

From the humble beginnings of pressure-based resistive screens to the cutting-edge projected capacitive displays powering today’s most advanced workstations, the evolution of touchscreen technology tells a story of continuous innovation. Each stage of development addressed the limitations of the one before, creating a spectrum of options for different applications.

iPlanTables leverages the very best of these innovations by integrating projected capacitive touch screens into every workstation model. For professionals who rely on precise digital interaction—whether reviewing complex construction plans or collaborating in real-time—this technology ensures that their tools are as advanced and dependable as the projects they manage.