In the fast-paced world of construction management, architectural design, and public-sector planning, touch interface reliability isn’t a luxury—it’s a necessity. That’s where PCAP technology comes in. Powering some of the most responsive and durable interactive surfaces available today, Projected Capacitive has revolutionized how professionals interact with digital content.

Whether you’re reviewing plan sheets in real time, collaborating across teams, or navigating dense GIS layers, a seamless interface can be the difference between progress and frustration. This blog will guide you through what projected capacitive touch offers, how it compares to other touch input systems, and why it has become the backbone of iPlanTables workstations.

What Is PCAP Technology?

At its core, PCAP technology uses a grid of electrodes embedded within the screen’s glass to detect changes in the electrostatic field caused by the touch of a finger or stylus. Unlike resistive systems that rely on pressure or infrared grids that depend on line-of-sight interruption, projected capacitive touch enables direct and instantaneous contact recognition.

It supports up to 10 or more simultaneous touchpoints and responds precisely even when users wear gloves or interact through a screen protector. This is particularly useful in environments such as construction trailers, planning departments, and public works offices, where protective gear is commonly worn.

How Does PCAP Compare to Other Touch Interfaces?

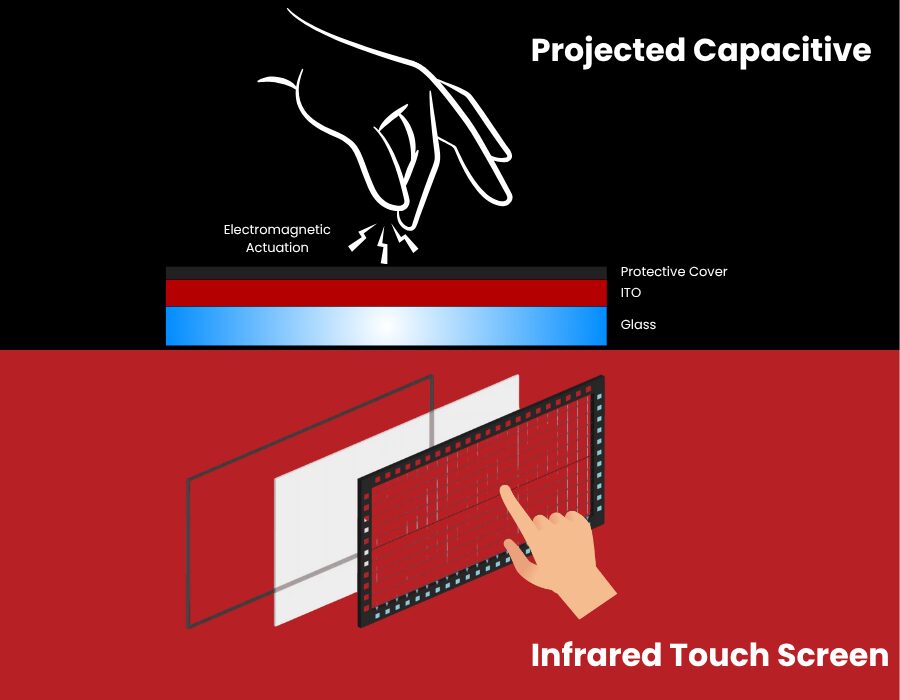

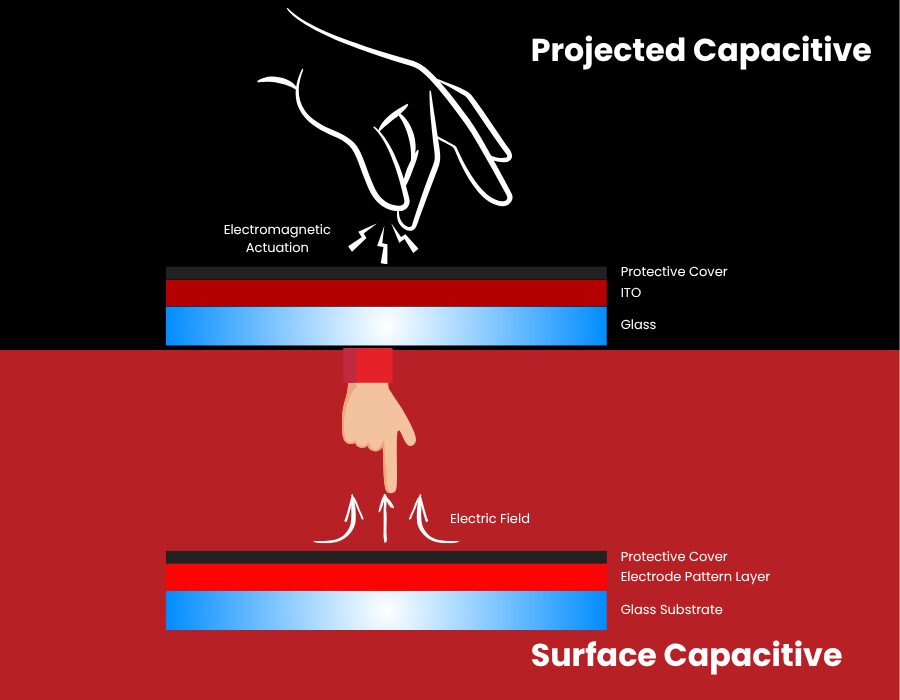

When evaluating touch systems, three major options dominate the commercial space: projected capacitive touch, infrared (IR), and surface capacitive. Each has its place, but they differ significantly in accuracy, durability, and application range.

Projected Capacitive vs Infrared

Infrared touchscreens detect interruptions in LED beams across the panel’s edges. While these panels are cost-effective and support multi-touch, they often misfire in dusty, bright, or outdoor environments—a common setting in municipal field offices or building sites.

In contrast, a projected capacitive system performs exceptionally well under challenging lighting conditions. It also remains accurate when mounted in vertical or angled configurations, which makes it ideal for mobile carts, wall-mounted units, or adjustable desktop systems.

Projected Capacitive vs Surface Capacitive

Surface capacitive systems offer good optical clarity but typically support single-touch input only. They also degrade over time as the conductive coating wears off.

Projected capacitive touch systems, with their embedded circuitry beneath the screen’s surface, avoid these issues entirely, delivering superior longevity and accuracy.

Why iPlanTables Chooses PCAP for Its Interactive Workstations

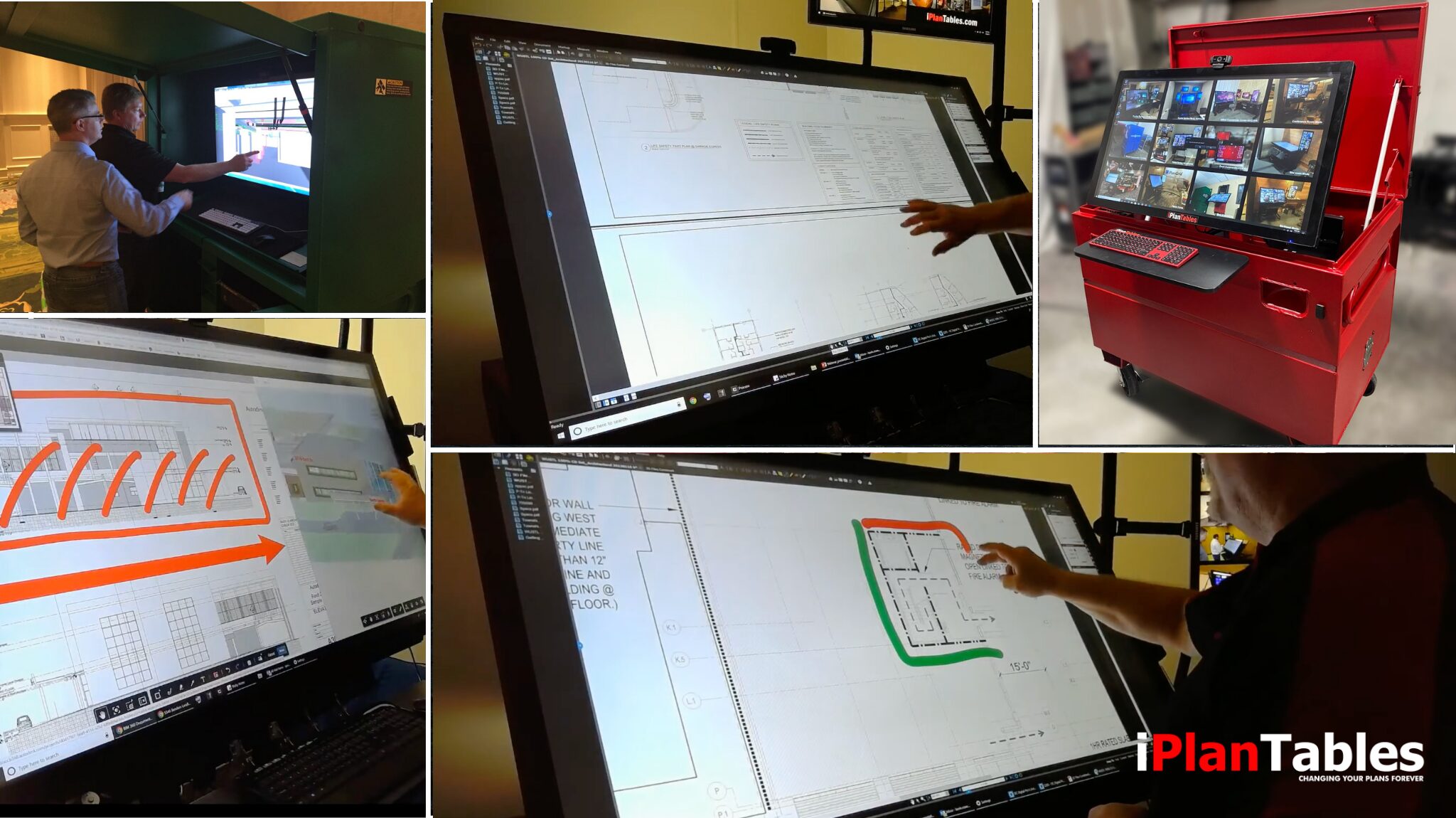

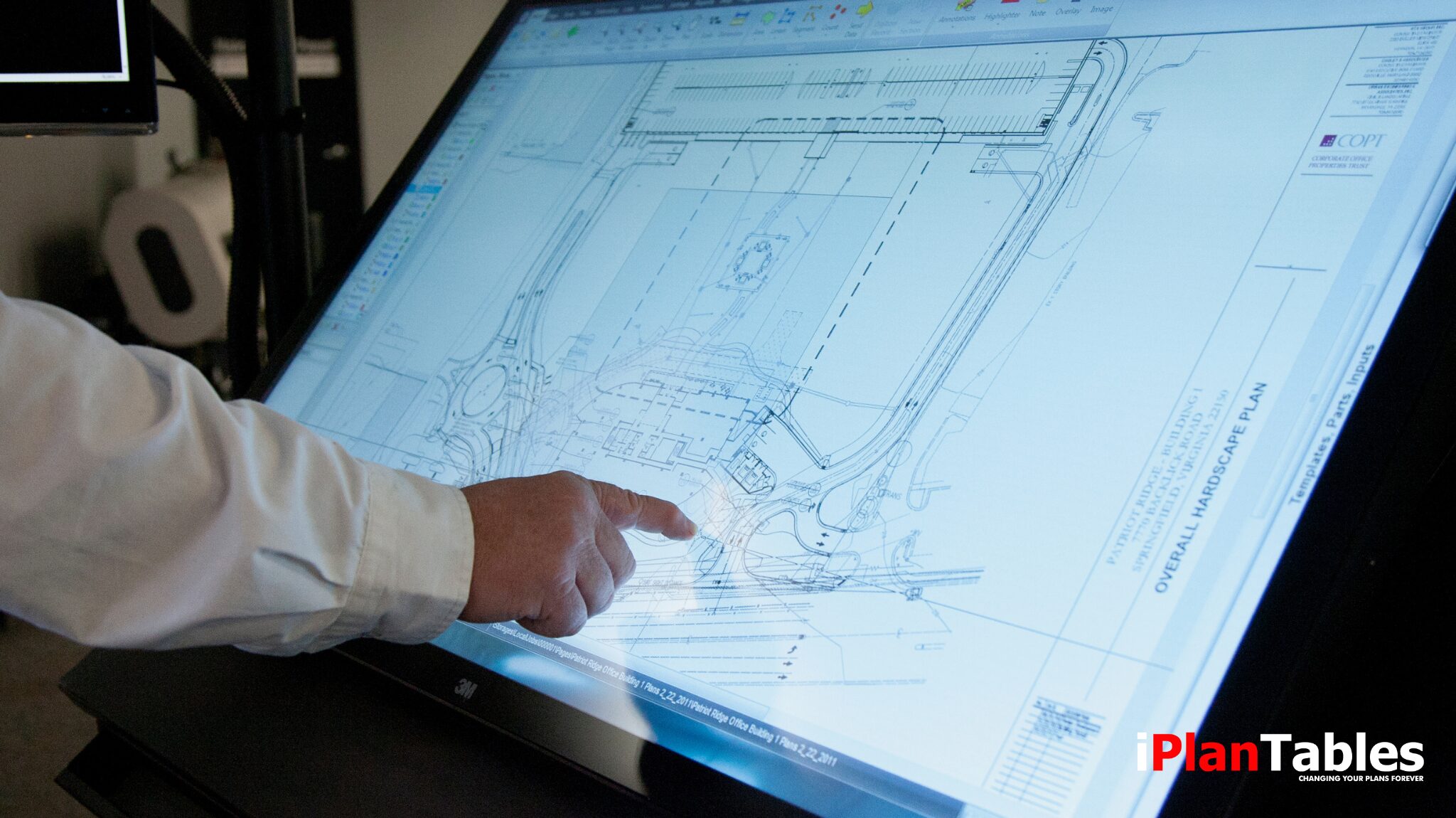

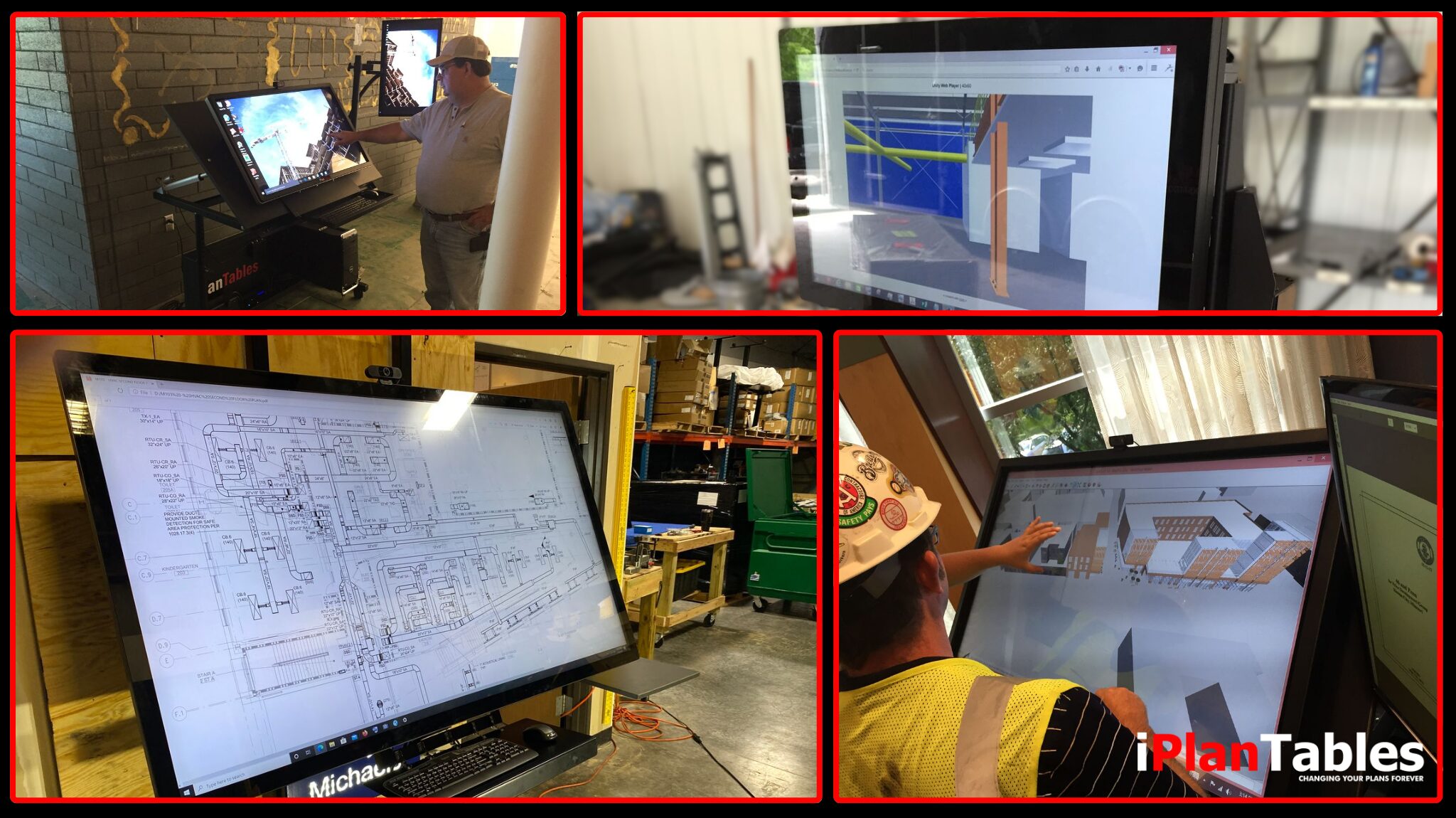

At iPlanTables, every touchscreen workstation is designed for high-stakes usage: plan reviews, takeoffs, BIM model analysis, and on-site inspections. In all of these applications, accuracy and responsiveness are non-negotiable. That’s why we use a projected capacitive interface in our product lineup.

Our displays are built to handle the pressure—literally and figuratively. Stylus-based annotations on large-format drawings? No problem. Gloved hands swiping through elevation views during site inspections? Flawlessly handled. Even in high-humidity regions or dusty job trailers, the interface remains responsive and precise.

PCAP Technology in Action Across Industries

Government agencies, contractors, utilities, and corporate facility managers are adopting iPlanTables workstations at scale because our solutions eliminate the input lag and precision issues found in lower-tier screens. Thanks to the projected capacitive interface, users can zoom, scroll, write, and annotate in real time with complete control.

For instance, a 2024 report by MarketsandMarkets projected the global market for capacitive touch panels to reach $15.3 billion by 2027, driven largely by growth in professional display use cases. Touchscreen integration isn’t just a consumer trend—it’s rapidly becoming standard infrastructure in industrial and enterprise settings.

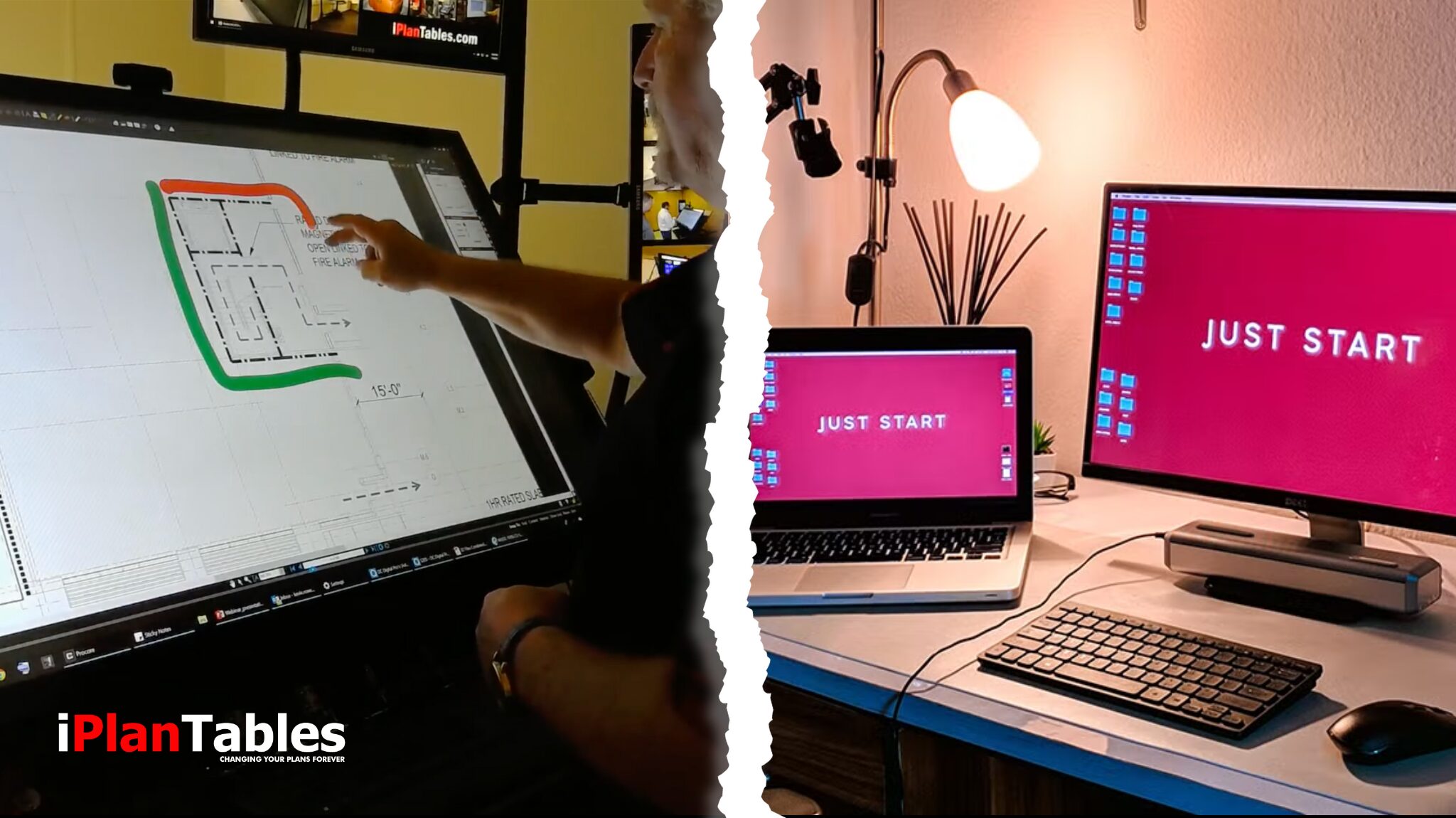

The Role of Multi-Touch in Collaborative Planning

One of the most powerful features enabled by the capacitive touchscreen interface is advanced multi-touch recognition. In iPlanTables workstations, multiple users can interact with the same digital plans simultaneously. Project managers can highlight issues while engineers take measurements—all without input conflicts or delays.

This opens the door to live markup sessions, remote collaboration via video conferencing, and real-time approvals during permitting. It transforms the screen from a static display into a dynamic work surface.

Enhancing Accuracy With Stylus and Palm Rejection

Another standout benefit is stylus support combined with palm rejection. This is essential for precision work such as redlining PDFs, drawing technical notes, or signing approvals digitally. Projected capacitive touchscreens automatically distinguish between intentional pen input and accidental touches from the hand resting on the surface.

According to Statista, digital stylus usage across industrial sectors has grown by over 30% since 2020, particularly in design, logistics, and construction. iPlanTables workstations are engineered to take full advantage of this growth by delivering a natural writing experience that mirrors pen-on-paper clarity.

Built for Durability: Why It Matters

Many workstations are installed in rugged conditions—construction offices, emergency command centers, and remote trailers. Projected capacitive touch system screens excel here, too. Because the sensors lie beneath a layer of glass, they are far more resistant to scratches, temperature shifts, and surface contaminants than IR or resistive panels.

This durability translates into lower total cost of ownership. Fewer repairs. Fewer replacements. More uptime. When combined with heavy-duty casters, adjustable arms, and integrated CPU mounts, it becomes clear why iPlanTables workstations are trusted by over 1,000 municipal, commercial, and federal agencies.

The Future of Touch Interaction in Planning and Review

The demand for reliable, fast, and durable touch input will only grow. As building departments continue to digitize workflows and field teams embrace paperless inspections, tools like the iPlanTables workstation—built on a projected capacitive interface—will play a central role in streamlining operations.

A 2023 Dodge Construction Network study revealed that 88% of contractors found real-time markup and collaboration tools to significantly reduce rework and delays. When those tools are powered by ultra-responsive interactive surfaces, the productivity gains are amplified.

What Makes iPlanTables Different?

Unlike standard consumer monitors retrofitted for enterprise use, iPlanTables workstations are purpose-built from the ground up. We don’t just add a touch overlay—we build interactive ecosystems. Each unit comes with:

43″ to 86″ 4K resolution displays

Articulating and height-adjustable arms

High-performance processors and RAM

Optional side tables and keyboards

Stylus with pressure sensitivity and palm rejection

Industry-leading support and training

And at the heart of it all? Projected capacitive system—quietly powering the responsiveness, accuracy, and durability that our users depend on every day.

Ready to Upgrade Your Workflow?

If you’re still navigating critical documents using a mouse and keyboard—or worse, printing paper plans—it’s time to rethink your tools. iPlanTables interactive workstations built on projected capacitive touch solutions are more than just hardware—they’re productivity multipliers.

Final Word:

By embracing projected capacitive touch solutions, organizations gain a competitive edge. It’s not just about interacting with a screen—it’s about interacting intelligently. And with iPlanTables, that future is already at your fingertips.